About the Project

In this specific project we had work inside and outside of the west plant on the UTMB campus in Galveston Texas. The scope of work inside the plant was to remove an existing 4500-ton York chiller and associated piping.

In the space of the existing chiller we installed two new 2250-ton Trane chillers. All of the 18” chill water piping was routed in the crawl space and up through the floor to tie into the chillers. The 20” condenser water piping was installed above the chillers and tied in. A new 2,000,000-gallon thermal expansion tank was built outside the plant. We installed new 20” under ground piping from the plant to the tank area. The system contained three pumps and several control valves to make it work. We also installed a 15-meg gas fired turban generator to power the whole plant during a power outage.

In the space of the existing chiller we installed two new 2250-ton Trane chillers. All of the 18” chill water piping was routed in the crawl space and up through the floor to tie into the chillers. The 20” condenser water piping was installed above the chillers and tied in. A new 2,000,000-gallon thermal expansion tank was built outside the plant. We installed new 20” under ground piping from the plant to the tank area. The system contained three pumps and several control valves to make it work. We also installed a 15-meg gas fired turban generator to power the whole plant during a power outage.

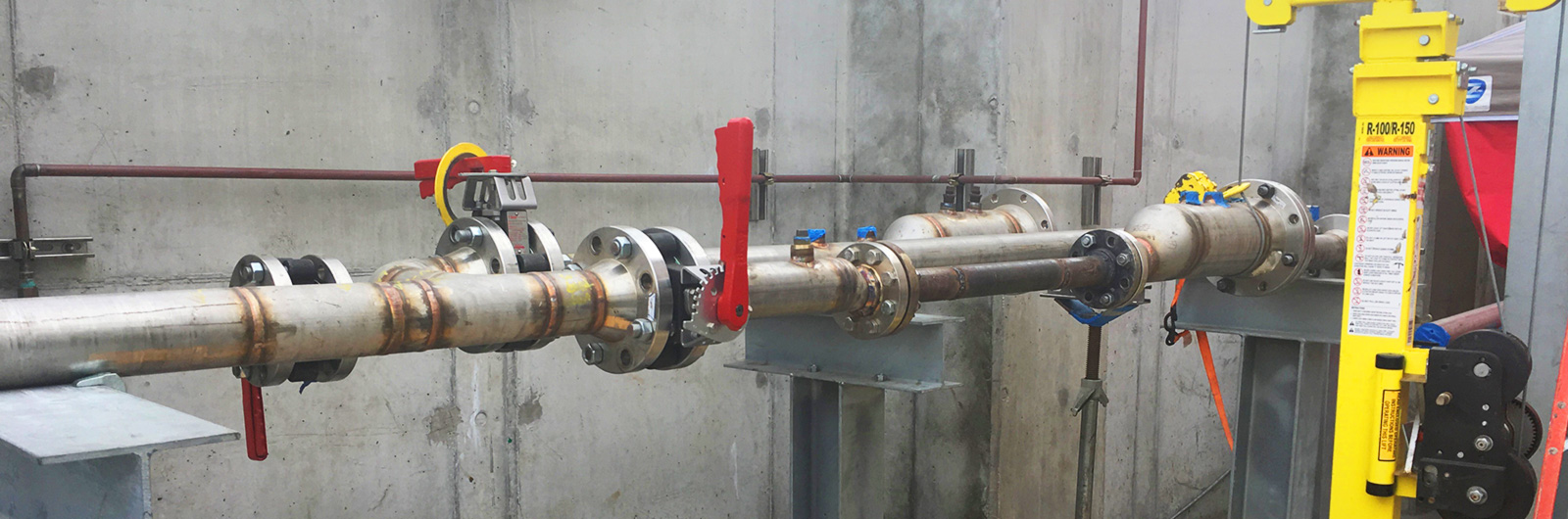

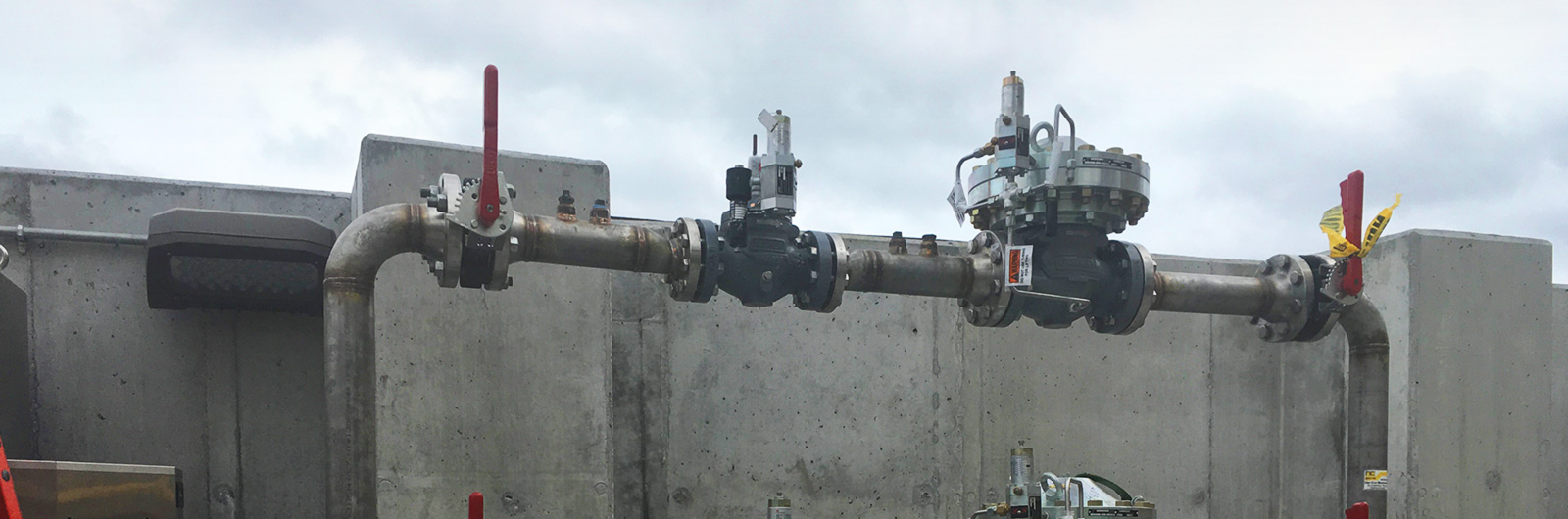

This system consists of stainless-steel lube oil piping, chill water piping to cool the oil and a chill water coil to pre-cool the air before entering the generator. Attached to the generator was a heat recovery steam boiler to supply the campus with steam for heating proposes. The 550-pound natural gas feeding these two systems was run in 6” stainless steel piping. The boiler would produce 250-pound steam to feed the heating system. There was a 15-foot water retention wall with flood gates installed around the plant. With this system the West central plant at UTMB in Galveston Texas would be able to run on its own power during any storm that hits Galveston island and supply the hospital with heating and cooling water as needed.